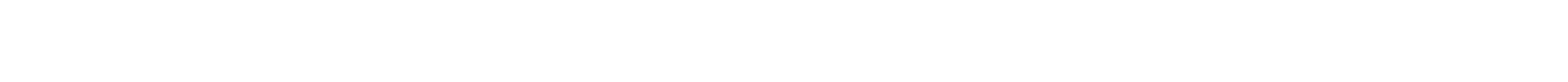

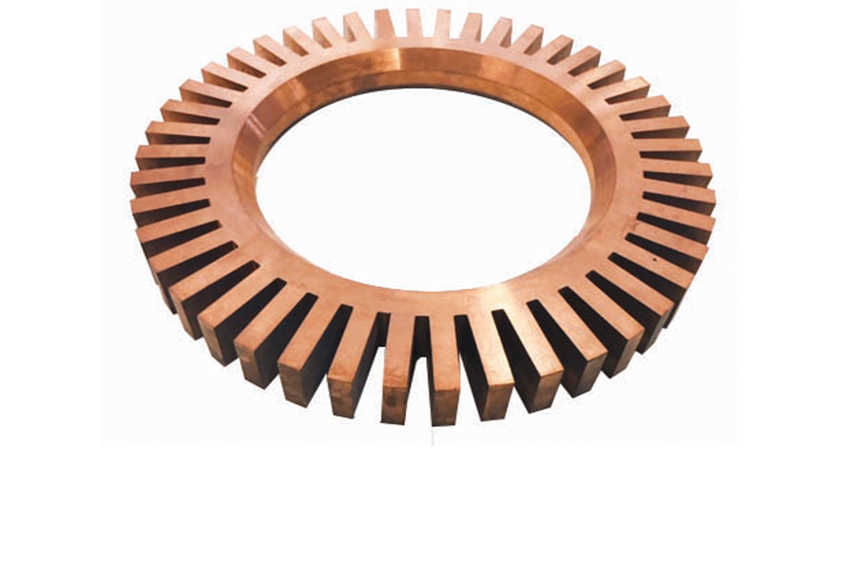

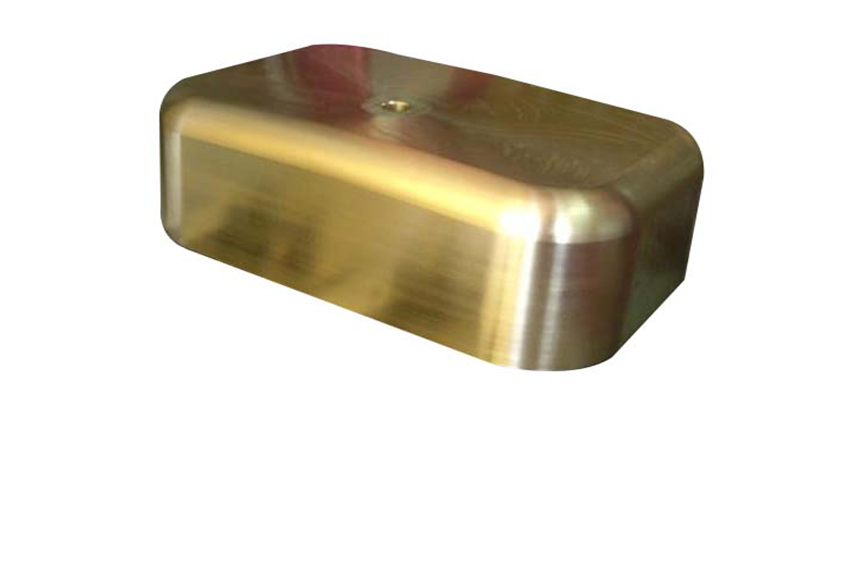

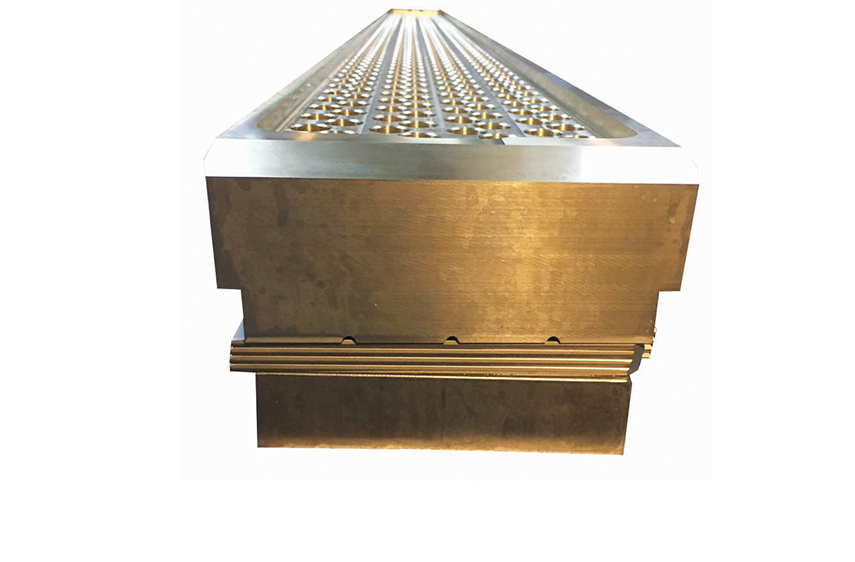

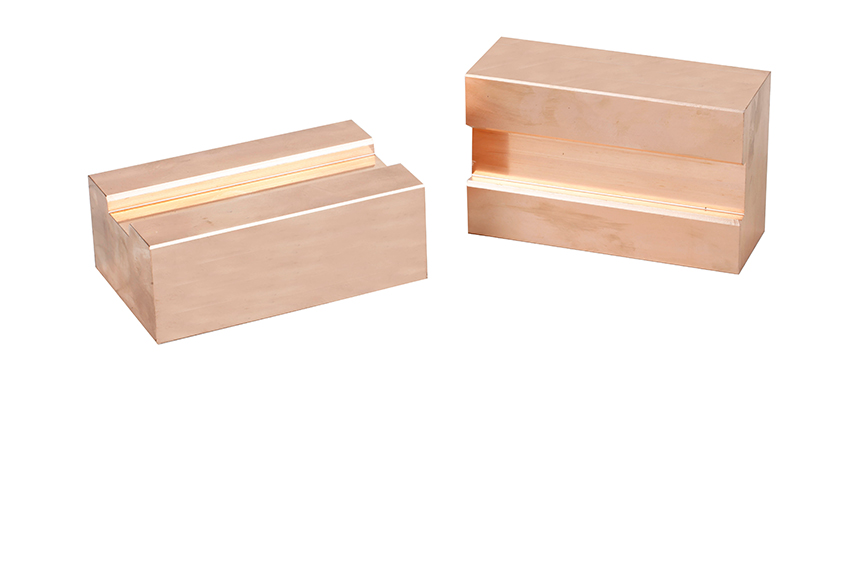

Electromechanical specialties:

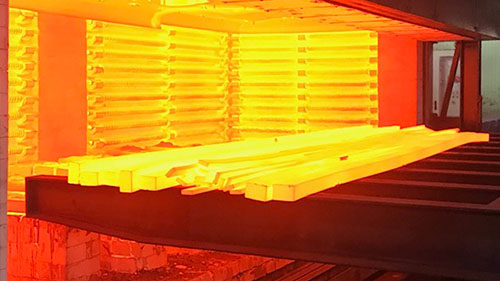

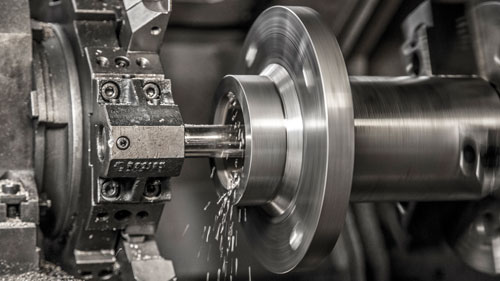

Focusing on high conductivity copper with fine grain size and excellent mechanical and physical properties.

Some of our industries served:

- Industrial AC Motors

- Railway / Traction Motors

- Mining / Atex Motors

- Marine Motors

- Power Generators

- Wind Turbine Generators

- Gas / Steam Turbines Generators